Undergraduate students at the Milwaukee School of Engineering (MSOE) have engineered a process to create red blооd cells, which will have a profound impact on medical care and solve the problem of blood shortages.

The production of artificial blооd is one of the holy grails in science. With a short shelf life of 42 days, reduced to a few hours if left unrefrigerated, and a low donor trend, there has been a clear need for blооd substitutes and supplements. Researchers in academia, the military, and the biopharmaceutical industry have had little success in their attempts to produce a viable product.

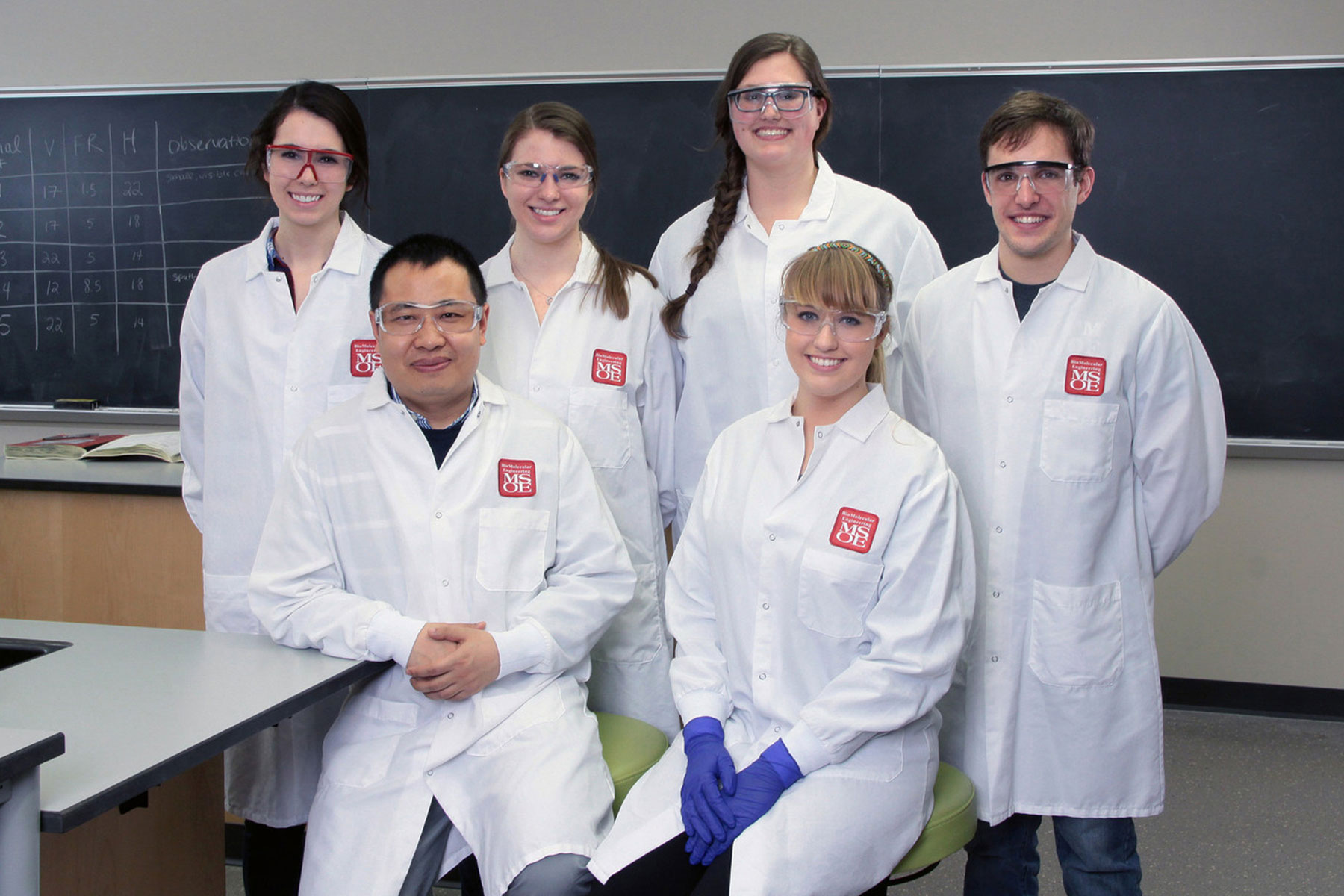

Assistant professor of biomolecular engineering, Dr. Wujie Zhang, is the principal investigator on a project to develop a synthetic red blооd cell material using natural polymers that are not harmful to human tissue.

“This allows for universal blооd typing with no screening requirements as well as a longer shelf-life,” said Dr. Zhang. “It is more cost-effective than traditional blооd donations, and there are no ethical or religious-related concerns with its use.” Applications include emergency situations in battlefield and refugee environments, and blооd centers.

Dr. Zhang originally advised an MSOE biomolecular engineering senior project team with Dr. Jung Lee, assistant professor, which was working to optimize an oral drug delivery system that used pectin-encapsulated curcumin to treat colon cancer.

But they discovered that the structure of the pectin hydrogel very closely resembled that of a red blооd cell. The students shifted their focus to engineering pectin hydrogel-based artificial red blооd cells. The microscopic artificial red blооd cells are suspended in an oligochitosan solution. Oligochitosan is a small sugar that holds the microcapsule structure.

Initial funding came from the Milwaukee I-Corps Program. Dr. Zhang and Dr. Lee then partnered with Gene Wright of MSOE’s Rader School of Business, and they received a $50,000 grant from the National Science Foundation I-Corps program, and training to transfer knowledge into real products or processes.

“We’re developing a product that will help people in the future,” said MSOE student Sydney Stephens.

A major project goal is to scale down the size of the artificial cells and test their ability to carry oxygen. “We’ve created the exact size and shape of the red blооd cell,” said Kellen O’Connell, MSOE student. “In our trials, the cells have averaged seven micrometers in size. Real red blооd cells average seven to nine micrometers.”

This patent-pending applied research offers MSOE students real-life experience in developing and commercializing a new product in an interdisciplinary environment. Members of “The Heme Team” include Haley Steiner, Rebecca Schroeder, Nataline Duerig, Kellen O’Connell, Dr. Wujie Zhang, and Sydney Stephens.

The team is pursuing additional funding to further develop the product and commercialize it. “This is a unique opportunity we have at MSOE where science, technology and business can work together to bring value to the world,” said Wright.

© Photo

Milwaukee School of Engineering